What is an Impedance Analyzer?

An impedance analyzer is a device that uses a programmable AC voltage/current source, together with voltage and current measurement circuits, to characterize sample impedance over a wide range of frequency. For example, Solartron Analytical 1260A Impedance Analyzer provides EIS impedance characterization over more than 12 decades of frequency from uHz to tens of MHz.

This technology is essential for researchers working with new materials such as semiconductors, smart-materials, ferroelectrics, piezo-electrics, solid oxide, solid electrolytes, ceramics, polymers, OLED and others.

How do Impedance Analyzers work?

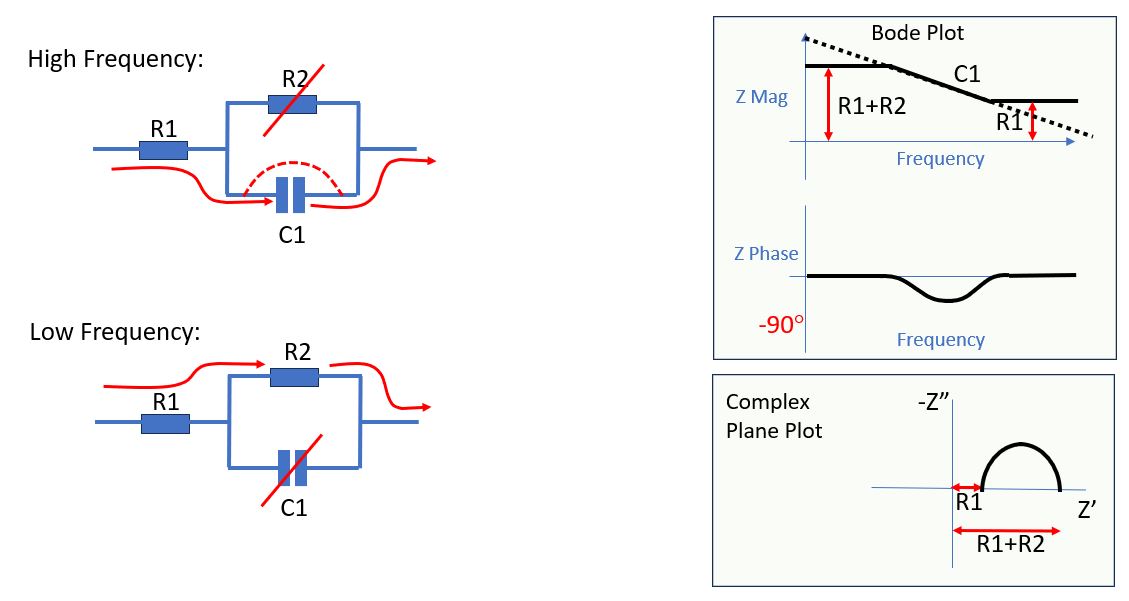

In most cases impedance analyzers apply sinusoidal waveform to a sample at a set frequency and measures the AC voltage and current across the sample. The ratio of these values gives the impedance. For resistive samples the voltage and current waveforms are in-phase, but for capacitive or inductive components, a phase shift occurs. Hence the sample is fully characterized by sweeping the frequency of the sinewave over a wide range.

What happens when the sample impedance is very high?

Standard Impedance Analyzers can measure only upto the range of megaohm (MΩ). For ultra-high impedance materials such as dielectrics, measurements may extend into the gigaohm (GΩ) or teraohm (TΩ) range. In such cases, low current interfaces or femto-ammeters are used to convert tiny currents (pA or fA) into

measurable signals.

What happens when cable impedance gets in the way?

At high frequency or high impedance, cables and other systematic impedances can affect the accuracy of measurements. In this case, sample/reference techniques are often employed that measure known samples and use those measurements to compensate for the effect of cables.

What happens when materials change due to temperature variation?

Material properties often change across different temperatures. This is why samples must be tested at various high or low temperatures. In this case, systems are configured with furnaces or cryostats to enable detailed testing across a range of temperatures.

Special configurations

Advanced research may call for custom setups for sputtering, neutron reflectivity, thin-film tests, micro-electrodes, Van-der-Pauw, and many other test measurements. At SI, we offer tailored solutions for these applications—contact us to learn more.

What happened when components are combined?

For detailed material analysis, SI uses systems that combine electrical, thermal, and mechanical properties of insulators, dielectrics, and electronic materials. These systems include specialized accessories such as High Voltage Amplifiers, Cryostats, Furnaces, and Sample Holders for liquids, powders, and solid materials.